Shop By Category

Related Links

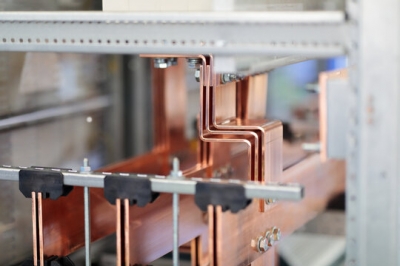

Bus Bar Metal Stamping

What Is a Busbar? (Definition, Uses, and Why Stamped Busbars Matter)

A busbar is a conductive metal components made from copper or aluminum that distributes electricity across circuits, panels, and equipment. It provides a high capactity and low resistance electrical pathway, making it ideal for applications where reliability, safety, and efficient power flow are essential.

Industries That Commonly Use Stamped Busbars

Stamped busbars are widely used in industries that depends on precise and efficient electrical distribution, including

- Electrical Vehicles: battery system, inverters, converters, and charging assemblies

- Renewable Energy: solar, wind, and energy storage system

- Data Centers and IT Infrastructure: high current distribution and UPS systems

- Industrial Automation and Control Panels

- Aerospace and Defense: lightweight precision electrical systems

- Telecommunications: network and backup power distribution

- Commercial and Residential Power Systems: breaker panels and power management units.

How Stamped Busbars Are Manufactured and Why Our Flow Forming Process Is Superior

Most manufacturers create busbars using conventional stamping or CNC bending. At Punch Tools, we take a more advanced approach. Leveraging 45 years of experience in metal forming, we developed Flow Forming, our patent pending technology that allows us to produced stamped busbar unlike CNC machines that bend one piece at a time, our process makes multiple bends in a single cycle, reducing the workflow from 3 steps to 1. This significantly boost productivity while saving time and money!

Custom Copper Busbars with Flexible Materials Thicknesses and Bend Options

We specialize in manufacturing custom copper busbars that are precision-engineered for your application. Whether you need simple layouts or complex geometries, we can produce exactly what your design requires. We also provide full support from the initial concept phase through full-scale production, ensuring a smooth and efficient development process.

Traditional metal stamping and bending methods often stretch the material, which can lead to inconsistent widths or thicknesses across the part during shaping or forming. This creates challenges in applications that require tight tolerances and uniform performance.

Our solutions is Flow Forming, also known as Linear Flow Forming, a specialized metal forming technique that shapes sheet metal under controlled pressure without stretching the material. This approach produces highly precise components with consistent dimensions and superior structural integrity. By pressing or drawing the metal into a die, Flow Forming ensures accuracy and excellent repeatability.

The process can also be combined with additional operations such as blanking, shearing, and notching, enabling us to deliver fully finished components within a single streamlined manufacturing workflow.

Optimal Busbar Performance

Like any electrical pathway, busbars require dependable short-circuit protection. Inconsistent widths, thicknesses, or openings can trap debris and increases the risk of failure, especially in high-current systems where even small imperfections can lead to serious damage.

To support our customers with high-precision, reliable components, Punch Tools offers a full suite of manufacturing capabilities, including:

- Progressive die heavy stamping

- Progressive die high-speed stamping

- Tool and die design

- Tool and die manufacturing

- Tool and die repair

- Tool and die maintenance

- Rapid prototyping

- Assembly services

- Waterjet cutting

Busbar Applications

- Batteries

- EV AC invertor (automotive)

- Battery pack

- Fuse panel

- Circuit breaker

- Charging inlet

- Drive units

- DC-to-DC converters

- AC-to-DC converters

- Heaters

- Air compressors

- Power converters

- Power inverters

- Battery Disconnect Units (BDU)

- Junction Box

- Gate Drivers

- Insulated-gate bipolar transistor (IGBT)

- Power Block

- MOSFET

- Power Distribution Unit (PDU)

- HV Charging Units / Superchargers

- Busway Systems

Metal Stamping Materials

With more than 45 years of expertise, we design the right tooling and processes to ensure every material delivers exactly what our customers need in their metal stampings. Common materials we work with include:

- Copper

- Steel

- Stainless Steel

- Carbon Steel

- Aluminum

- Galvanized Steel

- Brass

- Bronze

- Titanium Platinum

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2025 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.