Shop By Category

Related Links

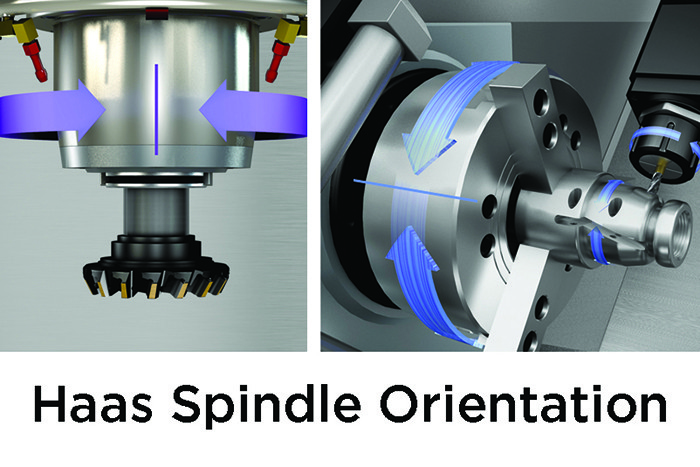

HAAS ST10Y CNC Lathe

The ST10Y CNC lathe from Hass is one of the CNC lathe machines we use here at Punch Tools.

Features:

- CNC Lathe w/Y Axis; 12″ x 16″ (305 x 406 mm) max capacity, 1.75″ bar, 16″ (406 mm) swing, ±2.00″ (±50.8 mm) Y-axis travel

- 15 hp (11.2 kW) vector drive

- 6000 rpm, A2-5 spindle

- 6.5″ (165 mm) chuck

- 2-station BMT45 turret

- high-torque live tooling w/C axis

What is CNC Machining?

CNC (Computer Numerical Control) machining is a precise and efficient manufacturing process that uses computer-controlled machines to shape, cut, and finish metal and other materials. CNC machines can handle complex designs with high accuracy, making them ideal for producing intricate parts and components used in various industries. Whether you're in need of custom parts or high-volume production runs, our CNC services are designed to meet your exact specifications.

A Lathe Machine uses an insert cutter with a removable tip, this is used to shape the outside of materials spinning in the chuck jaws with a series of precise cuts to the surface.

Our CNC Machining Services

We provide a wide range of machining services tailored to meet the needs of different industries and applications:

-

CNC Milling: Using multi-axis machines, we create complex parts with exceptional precision. Ideal for producing parts with intricate shapes and detailed features.

-

CNC Turning: Perfect for parts with rotational symmetry, we use high-speed CNC lathes to create precise cylindrical components.

-

EDM Drilling: For accurate hole drilling in various materials, we offer precision drilling with tight tolerances.

-

CNC Grinding: Our advanced grinding techniques ensure a smooth, precise finish on parts, especially when fine tolerances and surface finishes are critical.

-

Wire EDM: For parts that require intricate cuts or tight tolerances, our wire EDM services provide ultra-precise machining using electrical discharges.

Industries We Serve

Our CNC machining services cater to a wide range of industries, including:

-

Aerospace: Producing high-precision components that meet rigorous standards.

-

Automotive: Manufacturing custom automotive parts, including gears, brackets, and engine components.

-

Medical: Crafting parts for medical devices, ensuring high tolerances for patient safety and performance.

-

Electronics: Creating housings, connectors, and enclosures with precise dimensions.

-

Energy: Parts for power generation and oil & gas industries, where durability and performance are critical.

-

Manufacturing: Producing custom fixtures, jigs, and tooling for assembly lines.

Benefits of Our CNC Machining Services

-

High Precision: Achieve tight tolerances and intricate designs that manual machining can’t replicate.

-

Efficiency: CNC machines allow for high-speed, automated production, reducing lead times and minimizing human error.

-

Versatility: We can work with a variety of materials, including metals (steel, aluminum, titanium) and plastics.

-

Custom Solutions: From one-off prototypes to high-volume production runs, we offer customized solutions to meet your exact needs.

-

Cost-Effective: Reduce material waste and optimize manufacturing processes, offering a more cost-efficient solution.

Our CNC Machines & Technology

We utilize state-of-the-art CNC machines equipped with advanced technology to deliver precise, repeatable results:

-

Multi-Axis CNC Machines: Our 5-axis and 3-axis CNC machines handle complex geometries and high-precision parts.

-

CNC Lathes & Mills: Designed for turning and milling high-performance materials.

-

Advanced Software: CAD/CAM software ensures seamless design-to-production transitions, optimizing every stage of the machining process.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

.jpg)