Shop By Category

Related Links

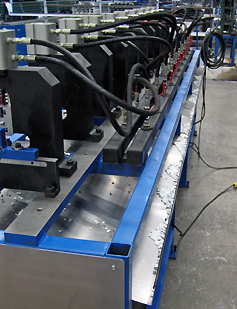

Gang punches dedicated to common process can dramatically increase through put and efficiency on the factory floor. Batch processing of extrusion on a job per job basis between departments sometimes means several low productivities means in each location. How about one high-productivity machine in several locations? The ten-station Hydraulic Gang Buster addressed these issues — such as portability, ease of hookup and high productivity.

Portability

Take the machine to the extrusion not extrusion to the machine. This allows greater flexibility in plant design and layout. First off the unit is very portable with the following features:

- Forklift moveable with balanced load and solid welded 2” square steel tube frame tube.

- Low center of gravity for stability during movement.

- Relatively lightweight — 1000 lb versus a press brake with sufficient tonnage weighing 10,000 lb and top heavy.

- The ten-station Hydraulic Gang Buster could be relocated across the plant in a few minutes and be punched in a different department right away. Machine utilization goes through the roof and bottlenecks are eliminated.

Ease of Hookup and Use

- 240 volt connection plug for hookup to cable drops around the plant.

- No need for hard wiring and a qualified electrician every time a move is needed.

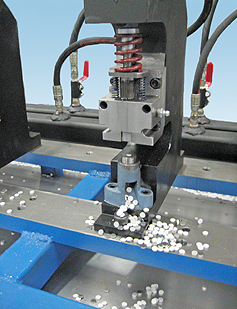

- Large slug tray solved prior clean up issues by retaining slugs to sweep into scrap bin.

- Factory floor was now CLEAN and free of slugs causing slipping hazard.

- Tethered foot pedal so operator has freedom to locate efficiently for loading and unloading.

Streamline Operations

Reduce equipment on the floor and increase productivity — this is where the unit proves its worth.

- The prior system had a make shift hole making novelty in each processing location including variations on drilling and punching one hole at a time that were developed over several years.

- Random lengths for every few parts required unique math skills to properly center holes from ends on the fly on old system.

- The Hydraulic Gang Buster allowed fast and easy visual setup over the entire length to the center part on the fixed pitch in one press cycle.

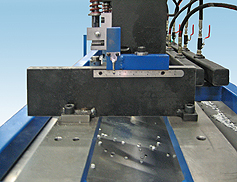

- Each punch head has a ball valve shut-off for the speed of customized punching.

- The operator can adjust the pitch centers doweled into a mounting table in minutes.

- The back fence setting is easily adjustable.

- Button dies and punch bodies are designed to fit inside the legs of extrusion.

- This manufacturing flexibility was the key to meeting the productivity goals.

Machine Specifications

- 240/480-volt hydraulic power pack (other voltages available to order).

- Foot print 144”L x 24”W x 32”H to table top/working height (approximately 48” overall).

- 10 variable pitch stations at 7 tons each.

- Flex-hose hydraulic connections.

- Punches and dies — off-the-shelf common components.

- Production rate — punch cycle time of 5 seconds.

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2024 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.