Shop By Category

Related Links

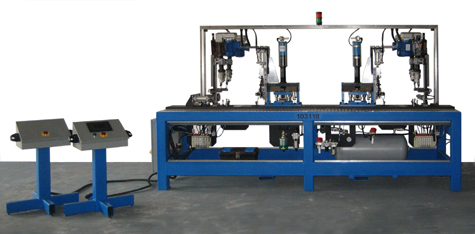

PLC Gangbusters for Aluminum Extrusion Punching

The PLC Gangbuster was designed for large multi plane punching applications. These typically involve right angle, U shaped or hollow channels that require precise hole reference positions to mating parts. The process often combines punching and drilling applications in the cycle.

1. Easy Hook Up

The PLC Gangbuster line is often powered by air for ease of hookup/installation and movement around your shop. The primary power in the PLC Gangbuster is air. The machine is controlled by plugging into a 110 volt power source – just keeping it simple.

This application called for punching 6 different hollow extrusions each with different lengths/hole patterns. The 6 made one set and the first phase of the project required 100,000 sets. The customers' prior methods used to process similar sets were so inefficient that the PLC Gangbuster made for a quick payback in dollars plus the added bonus of substantially shortening process time lines for the project as a whole.

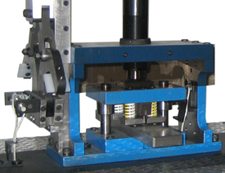

2. The Aluminum Extrusion Punch Cycle

The cycle starts by aligning the part to a datum point and then confirms the parts presence with sensors for key positions. Clamps are activated to compensate for bow and twist in the lengths and sensors at critical points again confirm part location. Once all the sensors confirm the part presence the punching and drilling cycle starts with a confirmation of actuation down and return to identify that all holes are successfully made. If any stations fail in the punching cycle the display panel identifies the location for the operator to address.

3. Dual Station

The PLC Gangbuster can be designed for a family of parts and in this case each machine is dual sided to process different extrusions – one on each side that can be activated independently of each other. This doubles the productivity as operators can load from either side and not have to wait for change overs to make the part in the set.

4. Aluminum Extrusion Punch Operator Function

This picture shows a single operator loading one side of the PLC Gangbuster. The machine is designed to allow independent loading and punching/cycling from both sides.

5. Aluminum Extrusion Punch Operator Consoles

This picture shows the tethered operator consoles that can be placed in the most convenient position based on operator preference and material location. Part times for floor to floor transfer are optimized with this freedom to move around.

6. Programming

The program comes with full fault reporting by station and sensors for easy troubleshooting.

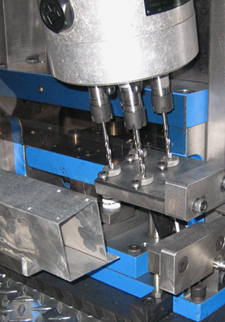

7. Aluminum Extrusion Drill Stations

Hollow extrusions sometimes require drilling instead of punching since a mandrel is required to punch without dimpling. These 4 drill heads make short work of the design hole layout in several locations.

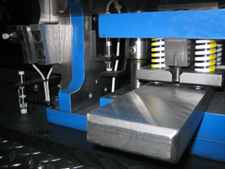

8. Aluminum Extrusion Punch Stations

These PLC Gangbuster punch stations work on the flanges of the extrusion for a simple yet elegant solution to the hole design pattern. The punch stations are equipped with sensors that confirm the punch cycle each time through for positive assurance that the cycle is completed in each location to prevent field installation issues down stream.

9. Aluminum Extrusion Punch Air Control Valve and Tanks

The air controls, valves and tanks are laid out spaciously to take advantage of the machine size allowing for easy access if maintenance work needs to be done in these areas.

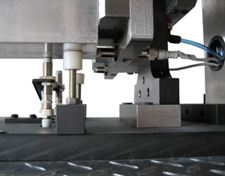

10. Aluminum Extrusion Punch Sensors

These shots show the sensor layout to positively confirm the correct location of the part before the cycle commences. The sensors can be disconnected at the mounting point making for ease of change out instead of having to pull the sensor lead all the way back to the control cabinet.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996